Note when checking form and order pulley:

1. Belt and pulley of our company can be

attachment or replacement of imported belt and

pulley.

2.

Please supply drawing when you order. We can also draw for clients as

their

supplied specification, hole, key way and

width.

3.

The tolerance of outside diameter, end bounce 7 wrap direction of pulley should

conform

to Form1,form 2 &

form3.

4.

Width of different specification of timing belt and pulley must conform to

form4.

5.

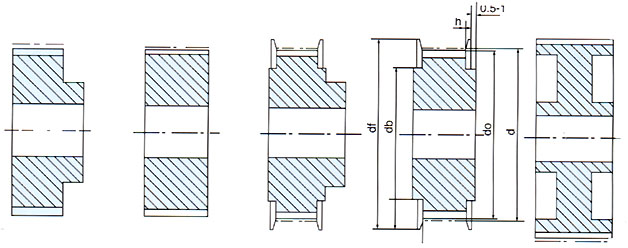

Outside diameter of pulleys and size should be as form's

regulation.

6.

We can also produce pulleys even sizes are not in the

form.

7. The

material of pulley mainly composed of carbon steel, if

possible aluminum alloy nylon

can

also be employed; if external diameter is larger than 250 mm, iron is

used.

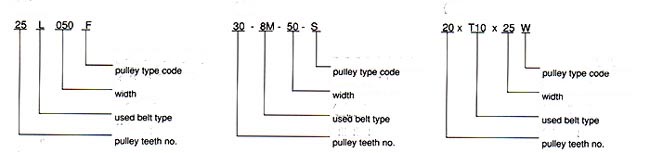

Representation of pulley

representation of T type pulley representation of ARC tooth representation of German T type pulley

Stype Stype Ftype Ftype

Wtype

Dimension of HTD type pulley(mm)

| type | pb | ht | R | S | r | angle |

| 3M | 3 | 1.28 | 0.91 | 1.90 | 0.3 | 14º |

| 5M | 5 | 2.16 | 1.56 | 3.25 | 0.48 | 14º |

| 8M | 8 | 3.54 | 2.57 | 5.35 | 0.8 | 14º |

| 14M | 14 | 6.20 | 4.65 | 9.80 | 1.4 | 14º |

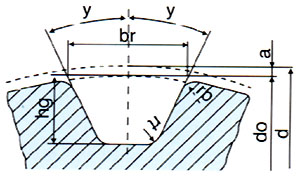

Dimension of HTD type pulley(mm)

| type | type |

V Grad |

rd | rt | 2a | |||||||

|

SE br |

N br |

SE hg |

N hg |

|||||||||

| difference | difference | difference | difference | |||||||||

| T2.5 | 1.75 | +0.05 | 1.83 | +0.05 | 0.75 | +0.05 | 1 | 25 | 0.2 | 0.3 | +0.05 | 0.53 |

| 0 | 0 | 0 | 0 | |||||||||

| T5 | 2.96 | +0.05 | 3.32 | +0.05 | 1.25 | +0.05 | 1.95 | 25 | 0.4 | 0.6 | +0.05 | 0.85 |

| 0 | 0 | 0 | 0 | |||||||||

| 10 | 6.02 | +0.1 | 6.57 | +0.1 | 2.6 | +0.1 | 3.4 | 25 | 0.6 | 0.8 | +0.1 | 1.85 |

| 0 | 0 | 0 | 0 | |||||||||

| 20 | 11.65 | +0.15 | 12.6 | +0.15 | 5.2 | +0.13 | 6 | 25 | 0.8 | 1.2 | +0.1 | 2.85 |

| 0 | 0 | 0 | 0 | |||||||||

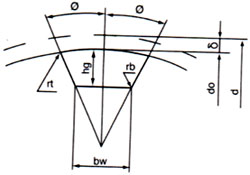

Dimension & tolerance of linear type pulley(mm)

| type | bw | hg | Ø+1.5º | rb | rt | 2 |

| MXL | 0.85±0.05 | 0.69 | 20 | 0.35 | 0.13 | 0.508 |

| XXL | 1.14±0.05 | 0.84 | 25 | 0.35 | 0.30 | 0.508 |

| XL | 1.32±0.05 | 1.65 | 20 | 0.41 | 0.64 | 0.508 |

| L | 3.05±0.10 | 2.67 | 20 | 1.19 | 1.17 | 0.762 |

| H | 4.19±0.13 | 3.05 | 20 | 1.60 | 1.6 | 1.372 |

| XH | 7.90±0.15 | 7.14 | 20 | 1.98 | 2.39 | 2.794 |

| XXH | 12.17±0.18 | 10.31 | 20 | 3.96 | 3.18 | 3.048 |

Pitch tolerance(mm)

| outside diameter pitch | difference allowed | |

| gap | gap allowed in 90º | |

| <25.40 | 0.03 | 0.05 |

| >25.40-50.80 | 0.03 | 0.08 |

| >50.80-101.60 | 0.03 | 0.10 |

| >101.66-177.80 | 0.03 | 0.13 |

| >177.80-304.80 | 0.03 | 0.15 |

| >340.80-508.00 | 0.03 | 0.18 |

| >580.00 | 0.03 | 0.20 |

Tolerance of outside diameter of pulley(mm)

| outside diameter | outside diameter |

| <25.40 |

+0.05 0 |

| >25.40-50.80 |

+0.08 0 |

| >50.80-101.60 |

+0.10 0 |

| >101.60-177.80 |

+0.13 0 |

| >177.80-304.80 |

+0.15 0 |

| >304.80-508.00 |

+0.18 0 |

| >508.00 |

+0.20 0 |

Allowable bounce of pulley end(mm)

| outside diameter | allowable bounce |

|

<101.60 >101.60-254.00 >254.00 |

0.10 outside diameter×0.001 0.25+[(outside diameter-254.00)×0.005] |

Allowable bounce of pulley warp direction(mm)

| outside diameter | allowable bounce |

|

<203.20 >1203.20 |

0.13 outside diameter×0.001 0.13+[(outside diameter-203.20)×0.005] |